Sustainability

Feel free to mistreat our products. They are made to endure all kinds of abuse. But nature isn’t. That’s why we use as much recycled plastic as we possibly can, invest in renewable energy, and support research of biomaterials. If it’s made by Nordiska Plast you can mangle it with a clean conscience. Time and time again.

Made in SwedenCall us control freaks all you want – we simply don’t want our products to be made so far away that we can’t see the factory from our kitchen window. All of our products are made in our manufacturing plant in Småland, Sweden. That way we can be sure that our employees are treated well, and that none of our products contain bisphenol A (BPA) or phthalates. Plus, nothing needs to be shipped across the globe since most of our customers live in the Nordic countries. |

|

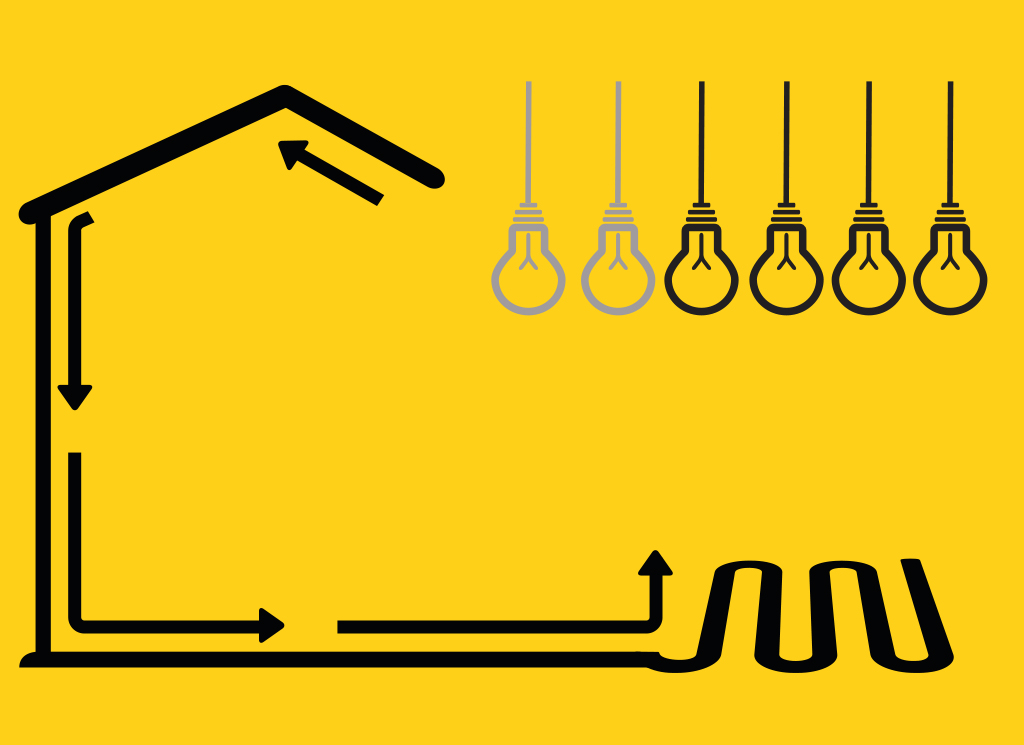

EnergyPenny-pinchers or not – we admit that we really like it when our electricity bill is as low as possible. Because saving electricity means saving the environment. We use our own excess energy for heating our premises which has enabled us to become selfsufficient heating wise. We have put sensors on our lights to keep them from shining when no one is around, and we have invested in modern hybrid machines that consume much less electricity than the old ones. Ever since we first started measuring back in the 1990’s we have cut our energy consumption by more than 40 per cent. |

|

RecyclingYou can expect a certain amount of spillage at a plant like ours. But instead of letting it go to waste we collect it all, grind it down and make new things out of it – bins, for instance. We even buy spillage from other factories. In an average year we reuse more than 500 tonnes of plastics. But we want our customers to be able to reuse as much as possible too. A Nordiska Plast product is made to last for many, many years. When you finally throw it in the recycling bin it will be ground down and made into a deck floor or maybe a bucket handle. Eventually the new item will have served its purpose and goes back to recycling again, or to waste incineration where we can get most of the energy back. |

|

Materials propertiesThe lunch boxes we make, to name an example, are designed to withstand daily use for years. Which means they have to be made out of a tough material, but perhaps not the same stuff we use to make mortar buckets out of. Simply put: the right material for the right product. We only use recyclable plastics, and all our dye is food-safe. We perform thorough lab testing where we simulate years of daily wear and tear. This way we can be sure that the materials we use don’t emit any particles, and are 100 % safe for people of all ages.

|

|

Green electricityIn 2007 we started talking to some other companies in the neighbourhood about setting up our own power company. It turned out to be one of those things that takes a lot of time to realise. In 2010 our electric cooperative was finally a reality and in 2011 we bought our first facilities. At the turn of the year 2019/2020, we installed approximately 4,000 square meters of solar panels that produce just over 300,000 kWh of green electricity per year. |

|

InnovationAt present day there is no viable way for us to use biodegradable plastics in our products. And bioplastics made from sugar canes would also impact the environment since it would have to be transported to us all the way from Brazil. These are some of the reasons why we want to help accelerate the development. For example, we have joined Stora Enso in a project trying to find a way to use wood – natural resources abundant in Sweden – to produce a material that has the right properties while being fully carbon neutral. We are involved in a number of collaboration projects focused on developing new, sustainable materials and manufacturing processes. |

|

Directives & CertificatesWith plastics manufacturing comes a great responsibility. We need to know everything about materials, processes, workplace safety and anything else that can have an impact on either humans or the environment. For the average person, these things tend to get rather technical. Luckily, there are tightly controlled directives designed to make it easier to know which companies you can trust. Nordiska Plast complies with the REACH regulation and all EU directives on plastics. We are members of the Swedish recycling organization FTI as well as the Normpack group that works to ensure that materials that come into contact with food are safe. We are also ISO 9001, ISO 14001 and ISCC Plus certified.

|

|